on orders over €80.

on orders over €80.

- Home

- Forst World

Forst World

THE COMPANY VALUES.

A SUCCESS BORN FROM PASSION.

For generations, FORST beer has been committed to preserving the pleasure of the art of brewing with passion and skill, offering FORST specialties which have always maintained the highest standards of quality.

A company with close links to its local area, to its values and to its traditions, keeping a deep respect for nature and the environment.

The wish to preserve brewing culture and the attention to detail that can be sensed throughout the company are also evident in the numerous FORST pubs, where beer enthusiasts can experience them in a convivial atmosphere.

With close links to the territory and its people, FORST beer is committed to the community with a strong sense of social responsibility, which takes shape in its support of numerous organisations and associations throughout Italy.

OUR STORY

TODAY

After over 160 years of history, FORST remains a family-owned business, now in its fifth generation: President Margherita Fuchs leads the company with her two daughters, Cellina von Mannstein and Cordula Wolf.

2021

FORST’s new lagering cellar was inaugurated.

2009

The first stone of the new brewhouse was laid in a ceremony.

1989

When Luis Fuchs passed away, his wife, Margarethe Fuchs, became president together with her two daughters, board members Margherita Fuchs and Cellina Fuchs Barth.

1969

FORST partnered with Weihenstephan brewery, becoming the official Italian distributor of Bavarian beers.

1986 – The Forst Group founded Aquaeforst, purchasing the Merano Mineral Water springs.

1933

The company was transferred to Luis, the son of Hans and Fanny Fuchs. Over the next 56 years, he took the company to new heights in terms of quality and technology.

1917

Following the death of Hans Fuchs, his wife Fanny took over. With her entrepreneurial spirit, she led the company until 1933.

1863

Josef Fuchs purchased the brewery, with a very limited production (around 230 hL, or 204 barrels) and the adjacent parcel of land. With the support of his wife, Filomena, the company flourished.

1857

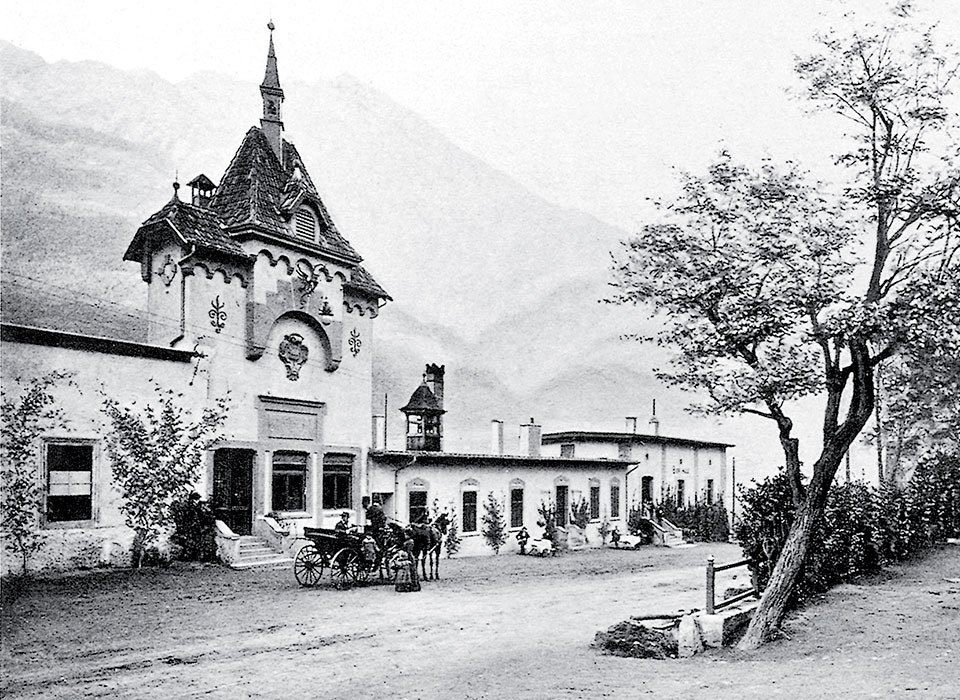

Two entrepreneurs from Merano, Johann Wallnöfer and Franz Tappeiner, founded FORST beer.

They built the first facilities in the very same place the company still occupies today, which is distinguished by three essential requirements for producing beer: superb spring water, ample room at the bottom of a valley, and fresh air in a pristine natural environment.

THE PRODUCTION PROCESS

FROM RAW MATERIALS TO THE BREWHOUSE

The malt supplied by the malthouses is stored in large silos. The amount needed for a production batch is then ground and mixed in the mash tun along with spring water from Marlengo mountain, in order to obtain the “wort”. The wort is then transferred to a kettle, along with the hops, and boiled for about an hour. In this way, three main ingredients come together in perfect, complete fusion in the brewhouse: a liquid (water) a grain (barley malt), and a flower (hops).

THE COMPANY VALUES.

A SUCCESS BORN FROM PASSION.

For generations, FORST beer has been committed to preserving the pleasure of the art of brewing with passion and skill, offering FORST specialties which have always maintained the highest standards of quality.

A company with close links to its local area, to its values and to its traditions, keeping a deep respect for nature and the environment.

The wish to preserve brewing culture and the attention to detail that can be sensed throughout the company are also evident in the numerous FORST pubs, where beer enthusiasts can experience them in a convivial atmosphere.

With close links to the territory and its people, FORST beer is committed to the community with a strong sense of social responsibility, which takes shape in its support of numerous organisations and associations throughout Italy.

The production process

FROM YOUNG BEER TO AGED BEER

After adding the hops and boiling the wort, the solid particles that coagulate during the process are strained out using a special piece of equipment: the Whirlpool. The wort, now cooled, is then placed in the fermentation tank. Beer yeast is added, which transforms the sugars in the wort into alcohol and carbon dioxide. After the first fermentation phase, the yeast is removed from what can now finally be called “beer”, or more specifically, “young beer”. The fermentation process lasts 7-8 days at a controlled temperature. But this “young beer” still needs to age in order to fully express its extraordinary flavor.

The long aging process, which requires very low temperatures (below freezing) takes place in our lagering cellars, under the watchful eye of our master brewers. This phase naturally removes the components that make beer “sour”, turning the “young” beer into an “aged” beer. It is then filtered and bottled.

The result is a fresh, thirst-quenching FORST beer.

THE KEY TO HAPPINESS

Renowned for their fresh, subtly bitter flavors, our beers undergo constant quality control in order to preserve these features. The cutting-edge technologies used by our master brewers allow for continuous, stringent quality controls throughout each phase of production. What’s more, FORST beer only uses the highest quality ingredients, for its malt, barley, spring water, and hops.

ITA

ITA  DEU

DEU